Best Combination of Precision and Innovation

Our versatile portfolio includes customized high-tech-tools and production equipment. Our products set new standards in the industry!

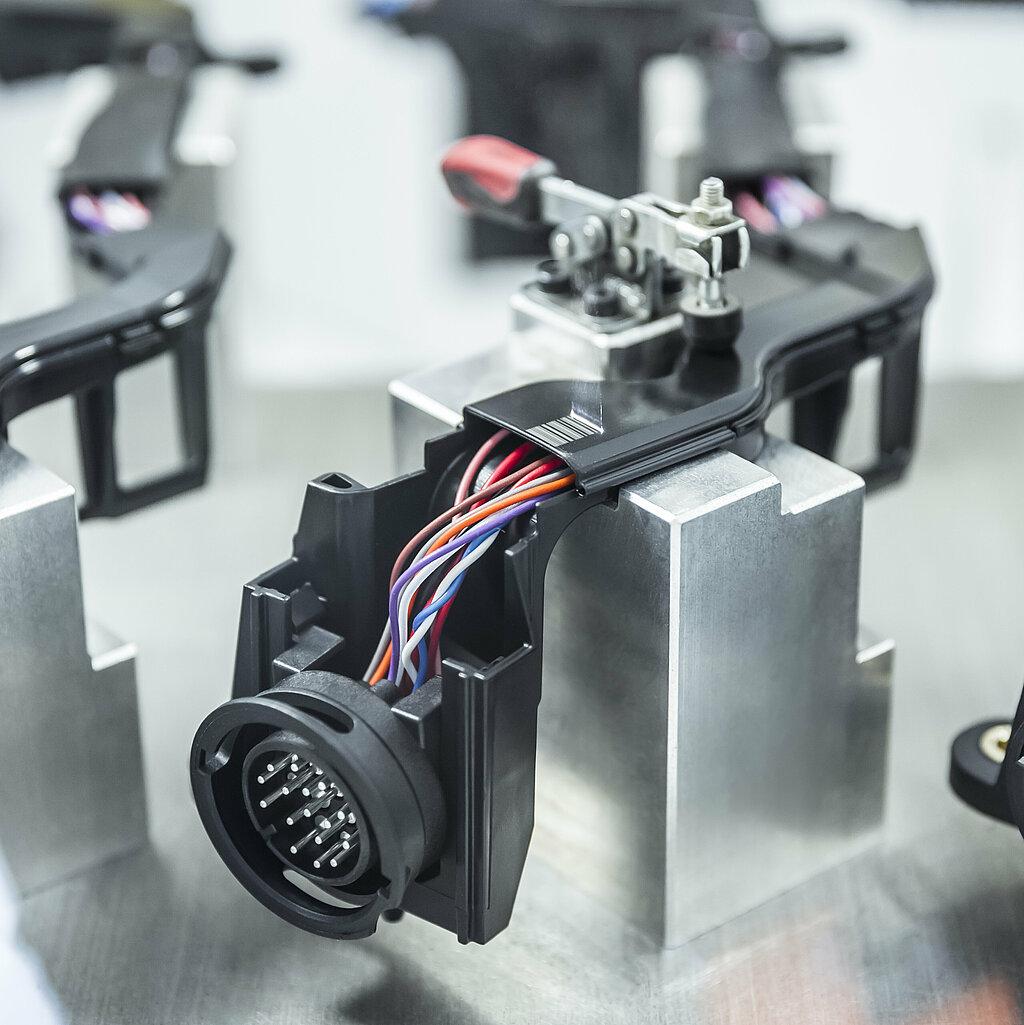

Customized Tools

We design and manufacture high-precision high-tech-tools – especially for plastics injection molding as well as stamping and bending technologies. The tools are adapted to individual customer requirements. Our employees ensure that the products meet the highest quality standards. In addition, they maintain the tools at all locations worldwide.

Our working environment is state-of-the-art. Digitization and automation have already been a part of our tool development and manufacturing departments for a long time – and we are setting new technological standards.

Benefits for Our Customers:

- Short development and delivery times

- The optimum concerning quality and costs

- Modular design with regard to increasing product variability

- Precision and maximum reliability in the application

- Durability and highest production efficiency

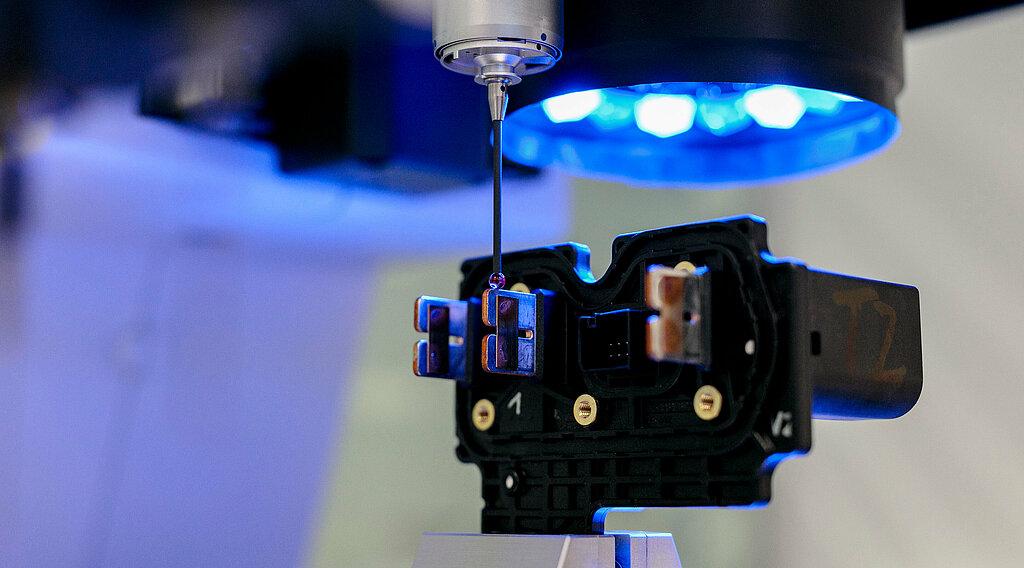

High-Tech-Special Machines

In our special machine department, we design and build customized production systems which are used at all our locations. The machines are fully tailored to individual customer requests. Our team of experts accompanies our customers worldwide – from the initial plant concept to series production and beyond.

Within this field digitalization and automation are also important factors: Our production systems meet all requirements of a smart factory. Thereby, cost-effectiveness and maximum efficiency always have top priority – whether we design semi- or fully-automated machines, small series or high-performance systems.

Our Production Systems Offer:

- Focus on high variability and complexity of the product portfolio

- Flexible and modular assembly concept as a basis

- Evaluation of real-time data

- Continuous optimization of the production process

- Improvement of the environmental balance