Mechanical Environmental Simulation

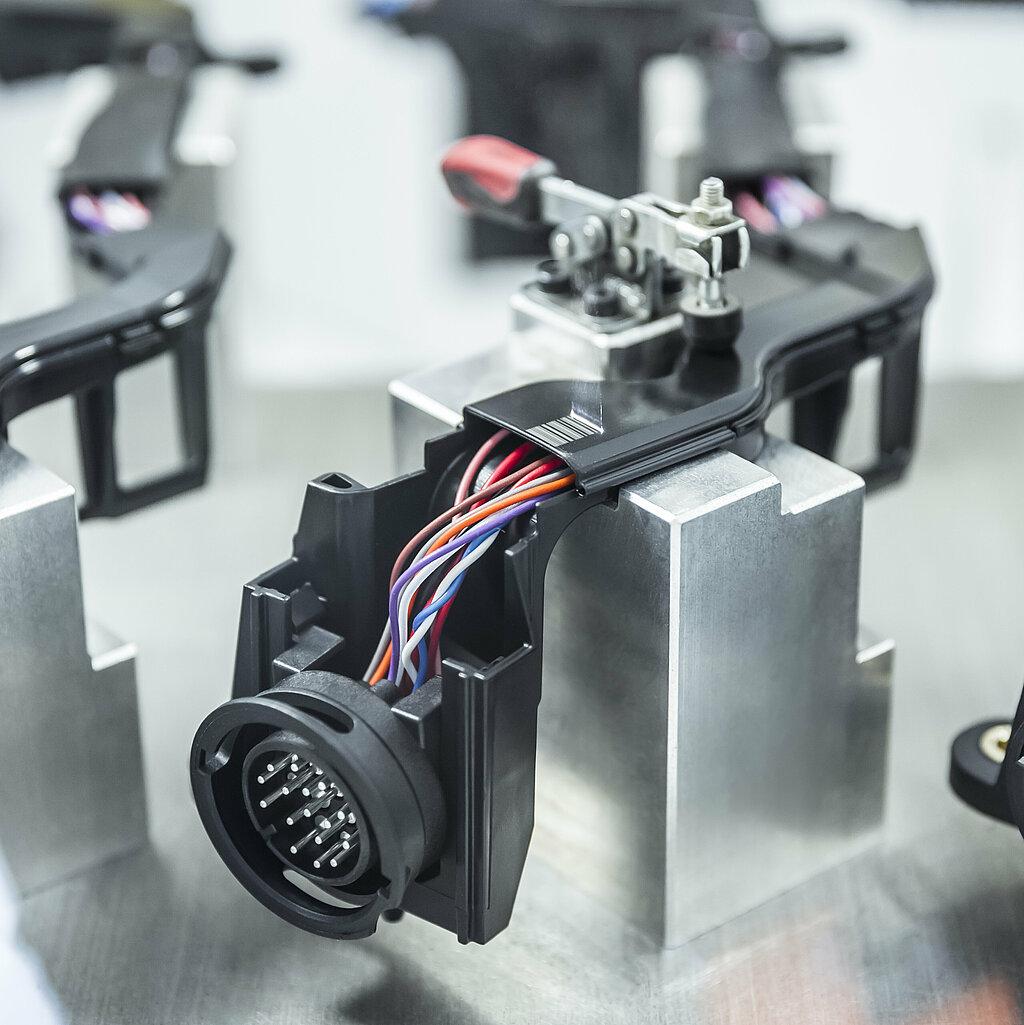

Mechanical environmental simulation is used to investigate the loads to which a product is exposed during operation. These tests simulate real conditions to ensure that the components can withstand the mechanical requirements.

Vibration and Dynamic Loads

During the vibration test, the product is subjected to vibrations (load changes) in order to assess the effects on performance and durability. This can be relevant for both field operation and transportation conditions. The test typically includes different frequencies and amplitudes to get a comprehensive picture of the possible loads.

By simulating these dynamic loads, potential weak points can be identified and weaknesses in the design or materials can be uncovered. This is crucial to ensure the reliability and safety of the product in real-life application scenarios and to avoid potential damage during transportation.

Vibration Modes

Shake It Up: Vibration Tests for Tough Products

An Extract of the Facilities

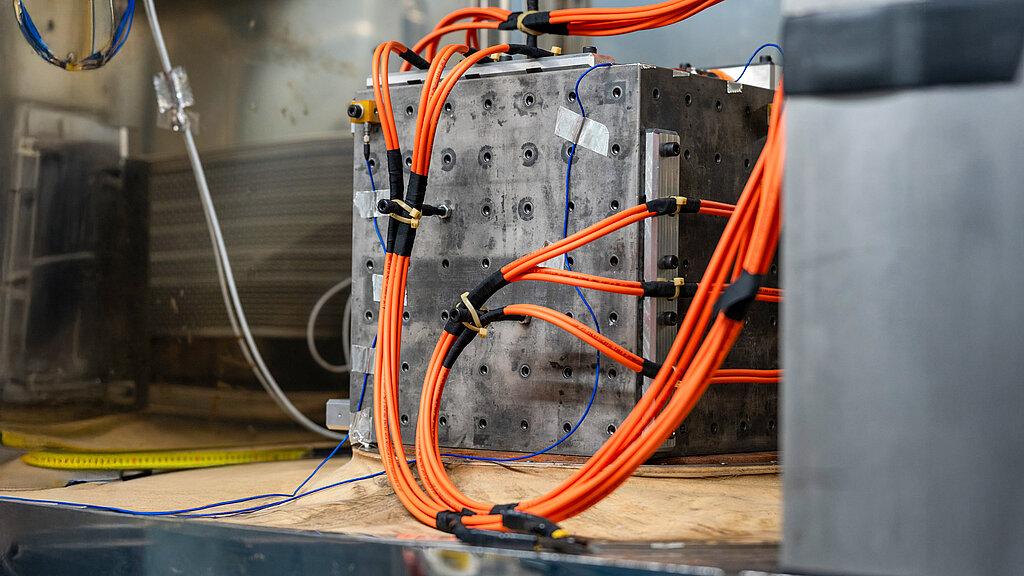

Vibration Unit 1 with Integrated Climate Chamber

Vibration System: A74 – IMV – 74kN

Dimensions Vibration Table: Cube with 350mm edge length

Hole Grid: M8 threaded inserts on 50mm hole grid

Climate Chamber: Temperature range: -70°C up to +180°C

Temperature Change: heating 5.5 K/min, cooling 4.5 K/min

Volume: ca. 1,150 liter

Vibration Unit 2 with Integrated Climate Chamber

Vibraion System: SAI60 – Unholtz Dickie – 35kN

Dimensions Vibration Table: Cube with 300mm edge length

Hole Grid: M8 threaded inserts on 50mm hole grid

Climate Chamber: Temperature range: -70°C up to +180°C

Temperature Change: heating 5.5 K/min, cooling 4.5 K/min

Volume: ca. 1,150 liter

Vibration Unit 3 with Integrated Climate Chamber and Sliding Table

Vibration System: K080-CE / IMV – 80kN

Dimensions Vibration Table: Cube with 350mm edge length

Sliding table and headexpander with 900mm edge length

Hole Grid: M8 threaded inserts on 50mm hole grid

Climat Chamber: Temperature range: -70°C up to +180°C

Temperature Change: 5 K / min

Volume: ca. 1,150 liter

I want to get in touch

Global Head of Laboratory