Environmental Simulation

Environmental simulation tests whether materials and components can withstand extreme temperatures, changing climatic conditions and the aging process. These tests are designed to ensure that a product can withstand the challenges of temperature changes, climatic conditions and long-term ageing.

Ensuring Reliability under Extreme Conditions

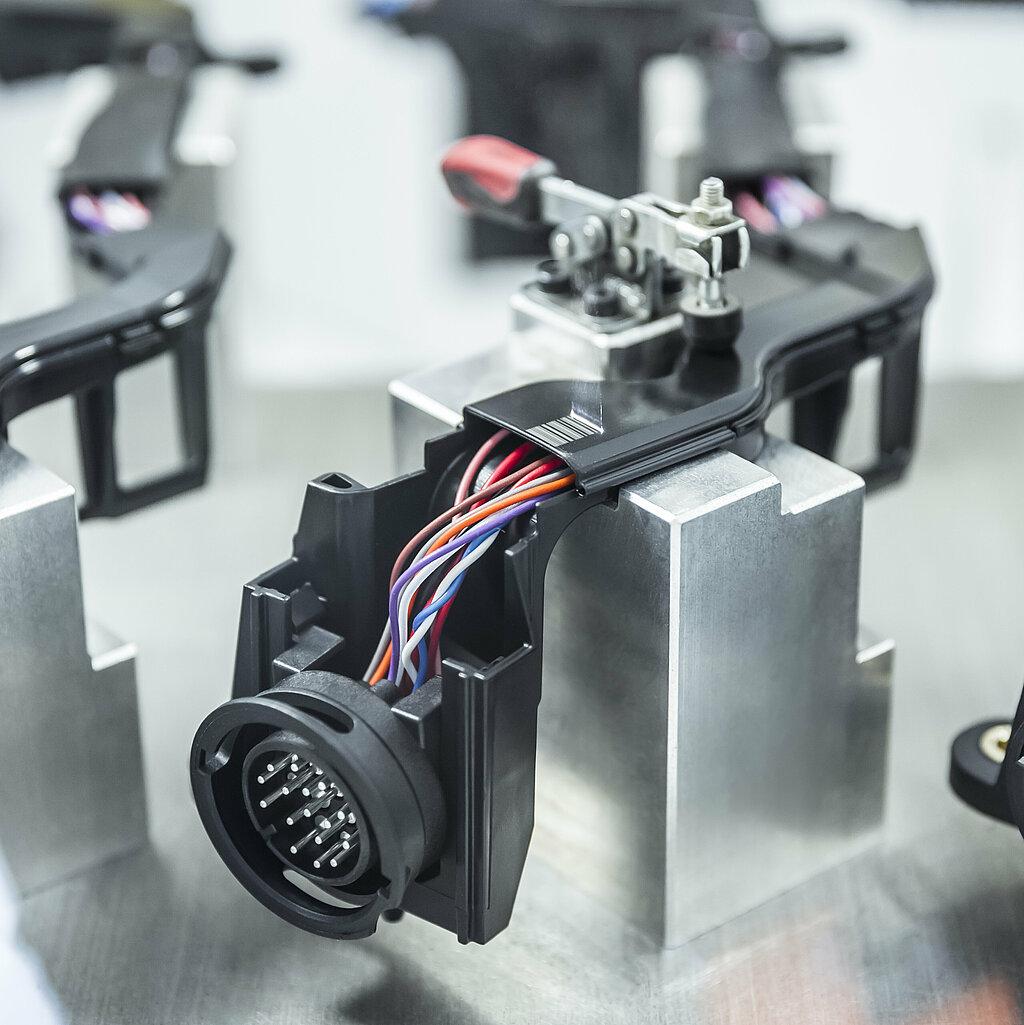

These tests check whether a product functions reliably at high and low temperatures and under various humidity and weather conditions. The test is carried out by simulating environmental stresses such as temperature shock tests, heat or cold tests, salt spray tests and simulation of liquid shocks.

These comprehensive tests can ensure the reliability and longevity of a product in different environments and over its entire service life.

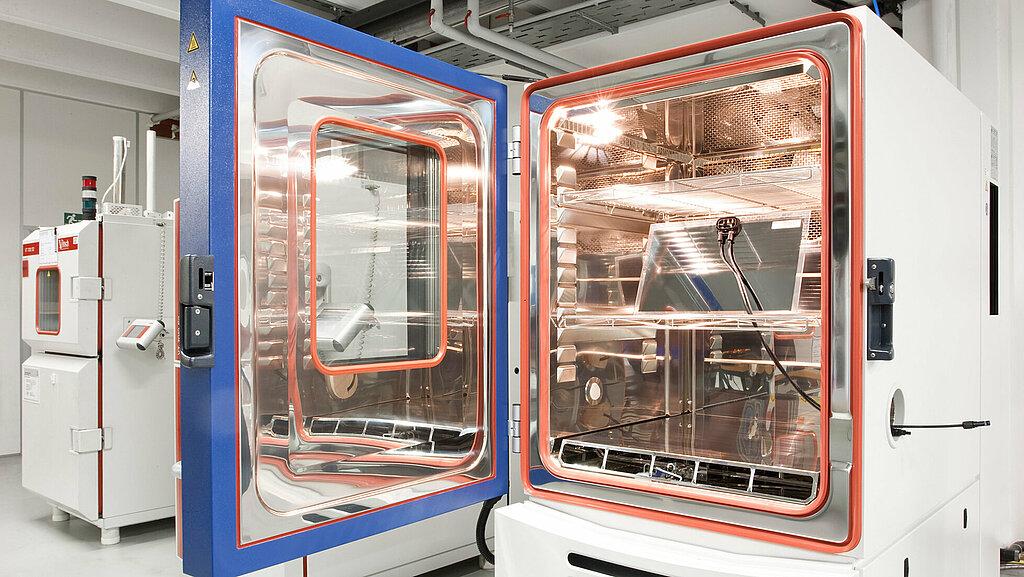

Equipment

Temperature Range: +5°C above ambient temperature up to +300°C

Convection: natural circulating air

Interior Volume:

5 cabinets with 240 liters

2 cabinets with 255 liters

2 cabinets with 743 liters

Temperature Range: -70°C up to +180°C

Interior Volume: 200 liters up to 350 liters

Temperature Change:

heating 3,1 K/min up to 3,5 K/min

cooling 2,5 K/min up to 3,5 K/min

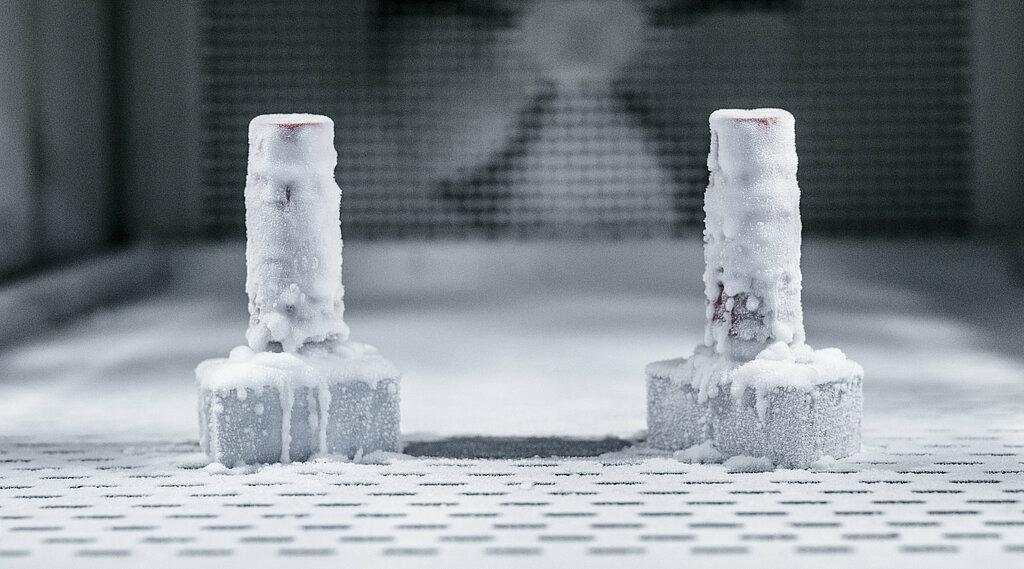

Temperatur Range:

warm chamber +50°C up to +220°C

cold chamber -80°C up to +70°C/+100°C

Transfering Time: <10s between warm and cold chamber

Interior Volume: 125 liters

Sample Weight: max. 50 kg

Temperatur Range: -70°C up to +180°C

Interior Volume: up to 600 liters

Temperature Change:

heating 3 K/min up to 7 K/min

cooling 3 K/min up to 6,7 K/min

Humidity Range: 10% up to 98% r. humidity at +10°C up to +95°C

Fluid: 5% Na-Cl-solution

Cold Bath: 0°C up to +10°C

Warm Chamber: up to +180°C

Transfering Time: <10s

Sample Weight: max. 20 kg

I want to get in touch

Global Head of Laboratory